What to look for in a laser cutter

We are continuing our series of posts on making money with a laser cutter/engraver or 3D printer. This post will focus on a laser cutter/engraver. So if you haven't purchased that laser cutter/engraver yet, here is a list of 5 things that should be at the top of your list of requirements.

5 things you need in a laser cutter

1. Power

Buy the highest power laser cutter/engraver you can afford. Power pretty much equals higher speed. The more power that you have available, the quicker you can cut or engrave in the substrate (the material you are working with) and with the is that ability to complete jobs quicker. Quicker jobs means more time for other jobs. You get the picture.

2. Table size

Get the largest table size that you can afford and will fit in your work space. Being able to take on larger sized materials allows provides several benefits. You can process jobs that require larger pieces, and you can process jobs using the same substrate and process type together in less time. If you cannot afford a larger table, just be prepared to spend some additional time for jobs that have many pieces if you cannot get them all onto the table at the same time.

3. Air assist

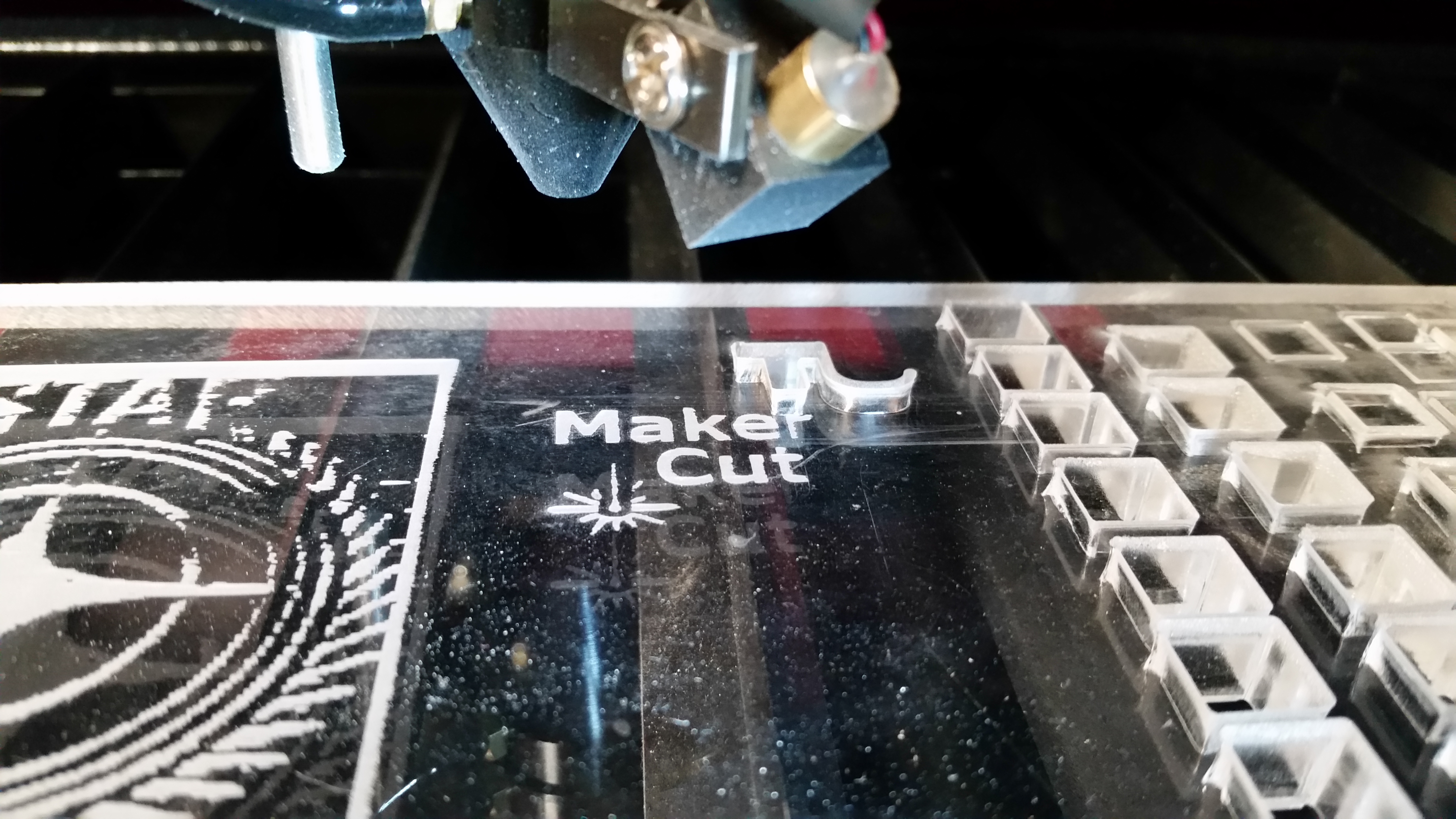

Air assist is a must! If you are going to cut any material other than paper you will need air assist. Looking at a machine that doesn't have air assist, keep looking. Cannot afford air assist as an option, keep saving until you can. There are many materials that you should not try to work with without air assist, like acrylic. One of the main reasons for air assist is to keep the lens clean, the other is to keeps fires to a minimum.

4. Rotary attachment

Some people will tell you that you do not need one, and they might be right. However if you are planning to work with any material that is round, you will need one. Eventually you will run into a job that will require a rotary attachment. If you choose not to get a rotary attachment, apply that money to more power or a bigger table.

5. Ventilation

It might be unexpected, but some machines come with no or inadequate ventilation systems. Fume extraction while processing a job is very important for several reasons; first, you need to remove the smoke from the laser beam as quickly as possible the more smoke there is the more the effective power will be reduced, second, some of the fumes can be noxious and if you are working in your house you won't want the smell wafting around. Make sure that the ventilation system can remove fumes in a reasonable time and if you can afford it look into a filtering system as well.

There are other considerations, like the size of your work space, electrical requirements, and so on. However, if you start with these five things you will be happier with your purchase. We will continue this series in upcoming posts. Give us feedback in the comments section below or sign up for email updates to know when we post. You can also follow us on social media.

Read the next post of the series – 4 THINGS TO REMEMBER – MAKING MONEY