Quick tips on assembly

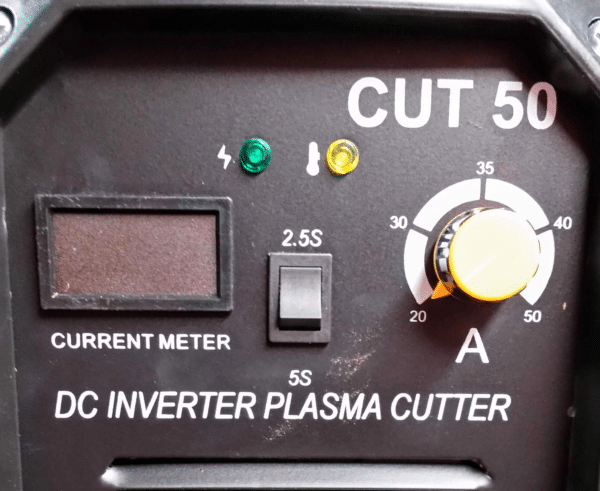

We recently purchased a Cut-50 plasma cutter and had a few assembly tips for those who also purchased one of these style of units that are made in China. Not everyone can afford a brand name plasma cutter, nor does everyone have the need.

After watching quite a few ‘unboxing' and ‘using' videos, we thought it might be nice to put a few observations out there. There are several different style units out there, we got one that has the pressure gauge on the regulator on the back to reduce the possibility of leaks. Which brings us to our first tip that we stole from the racing world (and the military).

Mount the pressure gauge so that the most used pressure, in our case 0.4 MPa (a little less than 60 Psi) is at the top (12 o'clock). This enables a quick check of the pressure before starting work.

Our second tip is to get yourself a 1/4″ x 1/4″ brass 90 degree elbow Male to Female fitting. We watched a lot of videos and the thing that stood out to us most was the pressure tubing sticking out the side of the unit in the back. Using the elbow allows you to reduce the amount of tubing and keep it withing the confines of the rear of the machine. We could have used one on the inlet side as well, and still might, which will reduce the strain on the regulator by not having to hold the weight of the air hose.