Watch the twitter-sphere for any length of time for tweets on laser cutting or engraving and you will see at least one a week talking how someone set fire to the laser cutter. While it may not seem like that big of a deal, think about this, most laser cutters utilize free-space optics. In other words, the laser travels through open space not through a medium like a fiber or wave-guide. This involves mirrors and lenses that will quickly become fouled with soot and debris when a fire occurs in the cutting area. Then there is the belts, wires, & contacts that are exposed to excessive heat and soot as well, which can melt insulation and belts, or warp the belt to prevent smooth operation of the drive system. Smell is something that will linger in the unit, sure it is cutting all the time by controlled burn, but the smell is different once you start full combustion of a material. So, how do you help ensure fires are kept to a minimum?

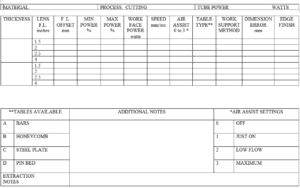

Clean the waste materials from the cutter after every job, this is especially important when the next job is using higher power settings that can ignite the waste material. Also, ensure that the air assist is on when running a job if your unit is so equipped. Power and speed also need to be set for optimal results, too much power with too slow a speed can cause a fire in the material being processed itself. This is where testing becomes important. Make sure that you have good ventilation while the unit is running, smoke can be ignited under the right conditions, the quicker it is removed the less chance of an issue.

Keep a fire extinguisher handy near the unit at all times, and know how to extinguish different types of fires. There are three classes of fires and each one is handled a bit differently, know what to do. Please do not become a screaming alpha.

Safety First!